How To Laser Cut Paper: What Is Laser Cutting Paper?

Learn more about the best practices for laser cutting with paper.

Laser cutting paper is a method that produces clean and precise cut edges with zero distortion from induced loads. It is unique in that an unlimited degree of finesse can be achieved with even the most basic equipment. Paper is best cut using CO2 lasers. The laser enables the cutting of high-precision and extremely small features while applying no mechanical load at the cut. The undistorted edge is an attractive feature. It produces cut qualities that are as good as those of single sheet processing by hard tooling while requiring no custom tools to be made. The optimal laser cutting settings depend on the paper thickness and the type of laser cutter. This article will discuss the techniques and benefits of laser cutting paper.

How To Laser Cut Paper

Laser cutting paper requires tight control of parameters and optimization of machine settings, allowing clean cutting with no burn or staining. Some trial is required, however, to get to these perfect settings, as not all papers are identical, either in weight (thickness) or cutting properties. Below are the steps in laser cutting paper:

- Select the appropriate laser cutting settings. Laser cutting of paper requires low power (about 10–15 W) and high feed speed to deliver a clean and stain-free cut.

- Position the paper on the cutting bed.

- Begin laser cutting according to the design requirements.

- Remove the finished product from the cutting bed.

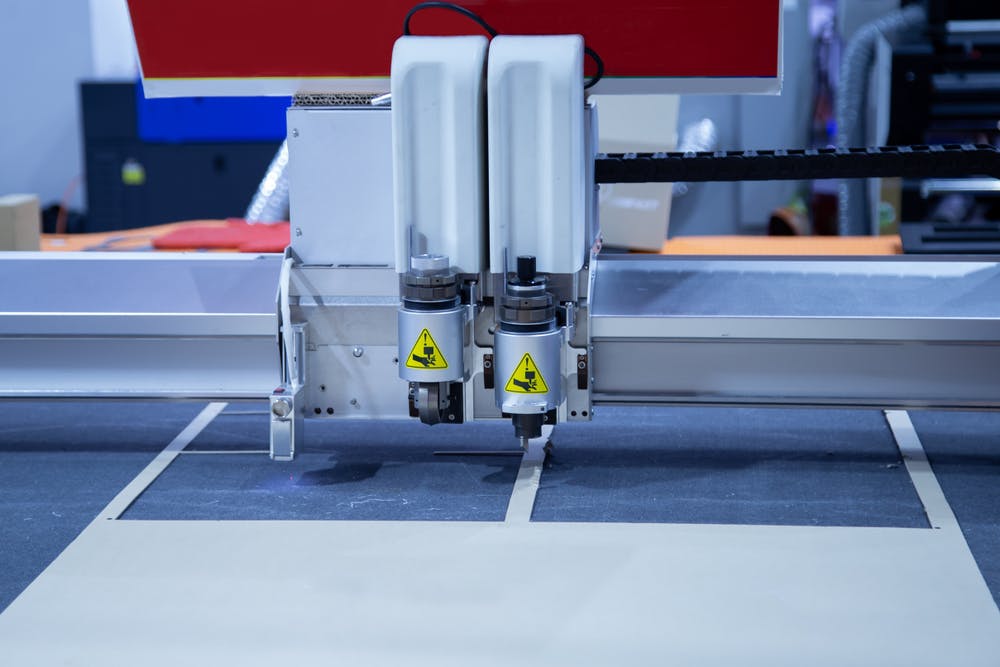

Figure 1 shows an example of a digital laser cutting machine cutting paper:

Digital laser cutter cutting paper.

Image Credit: Shutterstock.com/Itsanan

What Is the Advantage of Laser Cutting Paper?

Laser cutting of paper offers significant advantages over alternative precision methods such as CNC knife cutting, press knife cutting, and guillotine cutting. The most significant of these is the cost of custom equipment. Most processes for precision paper cutting require dedicated tooling. This tooling can be quite low in price for small-volume production. However, dedicated hard punch and die sets (for high volume) are very expensive and are suited to only one cut pattern.

The contactless cut afforded by laser processing of paper applies no forces to the cut area, so the flatness of the resulting cut is unparalleled. Processing costs are also low compared with most methods. Only dedicated punch and die cutting can compete in terms of throughput. Lastly, laser cutting paper is very flexible. The cut outline acts as a setup tool that costs nothing once designed and can be changed to another file almost instantly. This effectively makes the setup costs for a cut minimal and the changeover to a new cut pattern almost instant.

What Is the Disadvantage of Laser Cutting Paper?

One of the disadvantages of laser cutting is the up-front cost of laser equipment, which is higher than a pair of scissors. With laser cutting paper, even the simplest cut requires some skill in operating equipment and in setting up to make the cut safe and effective. In poorly set up conditions, the cut material can catch fire. While this hazard is not hard to avoid, the potential risk is high. Additionally, material stack heights are limited by laser focal depth. In comparison, a guillotine can cut hundreds of paper sheets in a single action, but only along a single linear edge. Paper material is best processed in single sheets, as air assist can lift upper sheets causing significant and potentially hazardous outcomes. Insufficient air assist will likely cause optics to become quickly degraded by condensed material.

What Is the Best Speed for Paper Laser Cutting With Presentation Parts?

High cutting speeds are recommended in processing paper. This speed maintains just sufficient dwell time for a complete cut without heat damage in the kerf. However, intricate elements and sharp changes of direction limit the feed speed and increase the potential for stepper motor errors in missing steps. This requires that intricate and complex cuts are performed at lower effective power and lower speed than long, straight cuts, so processing times will be longer.

A feed speed of around 150 mm/s is recommended for straight and simple cuts. Roughly 30 mm/s (with reduced power), on the other hand, is recommended for complex cuts with many changes of direction. These recommendations are drawn from experience with single sheets of 80–100 gsm white copy paper cut with a 20 W CO2 laser.

Colored paper, printing, and higher or lower weights will all affect cutability, so some trialing on waste material is strongly recommended. The ideal trial cycle is to increase feed speeds until the cuts just begin to fail, then decrease the speed by 5%. Perform this test cycle for both simple and complex cuts, to ensure cut quality under all conditions.

What Is the Best Power for Paper Laser Cutting with General Parts?

The best power for paper laser cutting with general parts depends on the type of paper used. For example, for the standard paper in the 80–100 gsm range, straight cuts at high speed are best performed at 15–20 W and at a feed speed of 150 mm/s. Intricate cuts at a reduced speed, on the other hand, will give good results at around 10 W and 30 mm/s feed rates.

How Does the Thickness of the Paper Affect the Wattage Required by the Laser Cutter?

The thickness of the paper does not affect the wattage required by the laser cutter. Generally, it is recommended to vary the feed rate instead. The common recommendation is to trial with the same recommended powers—5–20 W for straight, fast cuts, and 10 W for more complex cuts. Reduce the feed rate by 10% steps until you’re satisfied with the cut quality.

What Is the Best Setting for Laser Cutting Paper?

The best setting for laser cutting paper varies. Your setup is likely to differ in subtle ways from every other setup, so you must optimize for your conditions. Listed below are the recommended initial setups:

- Laser Power: 15–20 W for straight cuts and 10 W for complex cuts of a single sheet.

- Feed Speed: 150 mm/s for straight cuts and 30 mm/s at reduced power for intricate cuts.

- Focal Length: Minimum focal length lenses are recommended, and follow your machine's instructions for setting focal depth.

- Air Assist: Set low enough not to disturb the sheet while cutting.

- Exhaust: Venting to outside space, for health reasons.

- Machine Surface: A honeycomb or pin table is recommended, to reduce the effect of flashback.

What Are the Common Mistakes Made When Laser Cutting Paper?

The common mistakes made when laser cutting paper are:

- Excess dwell time (feed speeds too low) leads to an increase in the heat-affected zone (HAZ), smoke, and potential ignition.

- Use of excess laser power causes burning, smoke, and staining.

- Using insufficient laser power causes partial cutting.

- Use of non-optimal laser type—only CO2 and blue laser diode devices are well suited to paper cutting.

- Use of insufficient air assist allows optics to get obscured and staining to occur.

- Use of insufficient exhaust allows smoke staining to increase to visible amounts.

- Directly laying paper on the cutting table results in a flashback of reflected laser light damaging the rear surface.

- Poor choice of paper type prevents good quality cutting.

Which Laser Cutter Is Best for Use With Paper?

Paper cutting using a laser can be achieved with good results on most CO2 laser cutters, but feed speeds are quite limited on lower-cost machines. For excellent results and fast throughput of intricate paper designs, one recommended laser cutter is the Makeblock XTool 40W Smart Desktop Laserbox Rotary Laser Cutter. This machine offers some great features like cylindrical cutter/engraver capability using a rotator device, an excellent 40 W CO2 laser, great exhaust handling, and a neat, AI-based autofocus system that reduces setup times.

What Are Examples of Paper Laser Cutting Projects?

Some examples of paper laser cutting projects are:

- Christmas decorations, cards, gift labels, and place names for tables.

- Wedding invitations.

- Gift boxes.

- Layered and engraved 3D artworks.

- Traditional Chinese paper cuts for fans and storytelling.

- Indian shadow puppets.

What Are the Alternatives to Paper for Laser Cutting?

Some alternative materials to paper for laser cutting are:

What Type of Paper Is Not Recommended for Laser Cutting?

There are no plain papers that are bad for laser cutting. Some coatings, however, can cause problems, so extra caution should be put in place. For example, plastic coating and magazine gloss-coated papers need careful settings tests. As a rule, color can affect laser absorption. So large areas of color and multiple changes of color can affect cut speed/quality. Very thin papers such as tissue paper can also be hard to cut without ignition. The lightest of papers will likely move under the air-assist action needed to make good cuts.

Does Laser Cutting Burn Paper?

Yes, laser cutting burns paper. When the dwell time is too great, or the laser power is too high, it is quite easy to reach ignition. Careful settings control reduces the risk significantly. A CO2 extinguisher is a good accessory for your laser cutter. It is also possible to reach ignition from the flashback, whereby the reflection of the laser off the table uncontrollably heats the reverse of the paper.

Which Industries Make Use of Paper Laser Cutting?

A wide range of industries utilizes cut paper parts for a variety of purposes. This includes:

- Electronics: Electronics use paper laser cutting as insulating layers in PCB assemblies and as dielectric carrier media in capacitors.

- Printing: Printing uses laser-cut paper for bookbinding decorative elements.

- Arts: Artwork often uses cut paper for stencils.

- Craftwork Businesses: Craftwork businesses use laser-cut paper for a wide variety of decorative and practical uses.

- Manufacturers: Manufacturers often use laser-cut papers as location and separating tools in the mass production of non-paper products.

What Are the Best Materials for Laser Cutting, Including Paper?

The best materials for laser cutting are:

- Paper, card, and corrugated card.

- Man-made wood materials such as MDF, plywood, and hardboard.

- Natural woods such as fine-grained and resin-free woods.

- Natural materials such as leather and stone can be cut, although the careful choice of laser and higher laser powers are required.

- Plastic films and sheets.

- Metals such as aluminum, brass, steel, and stainless steel. Some pose difficulties, and all require higher-power devices for good-quality cutting, however.

Summary

This article presented laser cutting paper, explained what it is, and discussed how to laser cut paper and its best practices. To learn more about laser cutting with paper, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.