MDF Laser Cutting Services by Xometry

Xometry offers the highest quality MDF laser cutting services and can assist in the production of parts with intricate and complex geometries and excellent surface finishes.

MDF (medium-density fiberboard) is an engineered wood product made by compressing wood fibers into a dense board with an adhesive binder. MDF can be easily cut using a laser cutter. MDF is low-cost and has a consistent structure. This makes it ideal for furniture, musical instruments, and toys. Xometry offers high-quality MDF laser cutting services and can produce complex and detailed parts.

What Is MDF Material?

Medium-density fiberboard (MDF) is an engineered wood product that is made by compressing finely ground wood fibers into a flat, solid board under high pressures and temperatures. The particles are bound together by a resin, usually, a polyurethane binder such as p-MDI (polymeric methylene diphenyl diisocyanate) is used. However, some companies may still use the traditional formaldehyde-based resin binder which can pose some health risks, especially when laser cut.

The resin hardens during the compression and heating process, binding the wood fibers together. A wax is added to the material to impart some degree of water resistance since MDF boards will tend to swell when exposed to long-term moisture. Sometimes this is mixed in during manufacture and sometimes a wax sealant is painted onto the board after manufacture. MDF tends to be cheaper than normal wood because it is made from wood byproducts which are typically a waste material from processing wood. There are three general categories of fiberboard. They are:

- LDF: Has a lower density than standard MDF. In some cases, it is 30% lighter.

- Standard MDF: This is the most common version of MDF and is the easiest to source.

- HDF: This is a higher-density version of MDF and is stronger and heavier than standard MDF.

In addition to these main categories of fiberboard, MDF boards can be modified to have specific properties. For example, moisture and fire-resistant MDF boards are available, as well as boards with a veneer of real wood glued to the surface for aesthetic purposes.

MDF Laser Cutting Processes

MDF board can be either cut or engraved with a laser cutter. Because heat is applied for a very short time and is concentrated in a small area, there is little risk of the board catching fire. However, there is always a possibility this may happen and caution must be exercised. In addition, the heat from the laser will vaporize the resin binder. This process can produce toxic combustion by-products, especially if the board contains a formaldehyde-based binder.

- Laser Cutting

- Laser Engraving

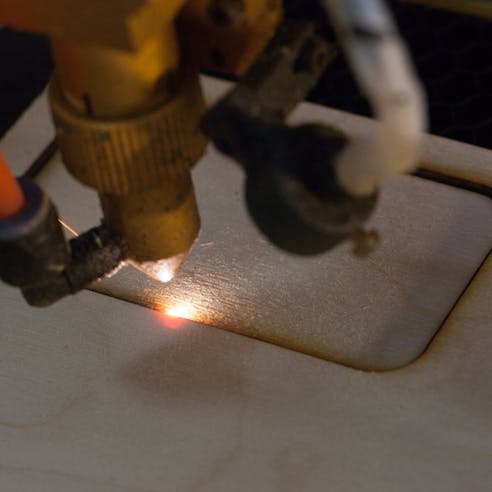

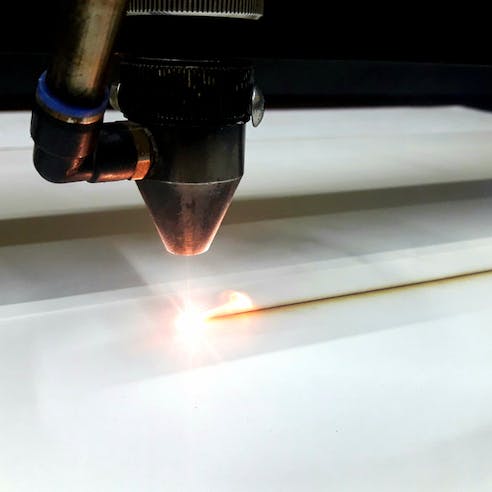

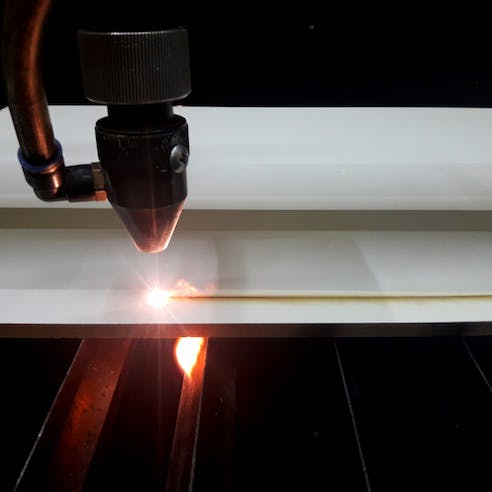

Laser Cutting

MDF boards can be cut into various shapes using a laser cutter without the risk of the board chipping, which is a common problem when processing MDF using typical woodworking tools. The laser will burn the MDF along a localized path and will produce a precise cut edge. Typically, a 40 W CO2 laser can be used to cut MDF boards up to 6 mm thick in a single pass. For thicker boards, up to 18 mm, multi-pass cutting may be required. Air assist can improve the quality of the cut while also preventing the laser optics from getting coated in combustion products which will reduce its effectiveness.

Laser Engraving

MDF boards can be laser engraved. However, it must be noted that the engraved area will take on a darker, “burnt” color. There are two engraving techniques that can be used on MDF board: raster and vector engraving. Raster engraving is ideal for designs that cover a lot of areas, such as pictures, for example. The laser will essentially color in areas designated by a computer program. For crisp line art, vector engraving is ideal, as it simply traces out the design.

MDF Laser Cutting Advantages

Listed below are some advantages of laser cutting MDF boards:

- Strong

- Cost Effective

- High Accuracy

- Easy Post-Processing

- Noncontact Processing

- Safety

Strong

MDF is an engineered wood product. Unlike normal wood, which has a higher degree of anisotropic properties, MDF has consistent mechanical properties. While it may not be as strong as some natural wood products, it has sufficient strength for most low-cost applications like utility furniture, shelving, or cupboards. Laser cutting allows for complex interlocking designs that can further increase the strength of MDF products.

Cost Effective

MDF is produced from wood byproducts. As such, it is significantly cheaper than natural wood. This makes it a more cost-effective material. While laser cutters are significantly more expensive than standard hand tools, they are able to quickly and accurately cut MDF boards which makes up for the initial setup cost.

High Accuracy

A laser is able to precisely cut out a design based on a CAD (Computer Aided Design) file. Since it is computer-controlled and involves little human intervention, the laser cutting process is accurate and repeatable. This is especially useful for intricate designs.

Easy Post-Processing

Very little post-processing is required after laser cutting MDF board. However, due to the thermal nature of the process, the edges of laser-cut MDF are black, which may be undesirable. These edges can be easily sanded or painted.

Noncontact Processing

MDF boards can easily chip, especially when cut using standard tools like circular saws or jigsaws. Laser cutting is a noncontact process. As such, it minimizes the potential for chipping of the board during cutting.

Safety

Laser cutting is generally safer than using standard woodworking tools. Multiple different hand tools may be required to achieve similar results to laser cutting, which all require significant experience to use safely. Laser cutting presents risks as well, but these can be managed by taking the correct precautions such as laser-blocking enclosures or laser-blocking safety glasses.

MDF Laser Cutting Disadvantages

Listed below are some disadvantages of laser cutting MDF material:

- Tends to Break Easily

- Susceptible to Moisture

- Heavy and Dense

- Difficult to Cut

- Burn Marks

Tends to Break Easily

MDF boards are held together with a polymer binder which, in most cases, keeps the board from breaking. However, the MDF board is not as strong as natural wood. It can break if handled or processed incorrectly, especially if complex, fine-featured designs are cut, which is something laser cutters are often used for.

Susceptible to Moisture

MDF boards readily absorb moisture and will swell when exposed to moisture for long periods. There are, however, special, more expensive variants of MDF that are water resistant. Laser cutting can cause the cut edges to be exposed to moisture ingress.

Heavy and Dense

A standard-sized MDF board requires two people to effectively handle, as it is very dense and heavy and can be difficult to place on a laser cutting machine. Its weight also makes it difficult to install the manufactured parts once they have been laser-cut. Light-duty MDF board is available, but this has significantly lower strength than standard MDF.

Difficult to Cut

MDF can be difficult to laser cut if the correct settings aren’t used. This may require some trial and error to get it working correctly. Multiple passes may be required for thicker boards and lower-powered machines.

Burn Marks

Laser cutting or engraving MDF will leave dark burn marks on all the cut edges and surfaces. These can be difficult to remove, especially if the design is complex and intricate, which can make it impossible to reach all parts of the workpiece with a sander.

In need of custom MDF laser cutting services?

Uses of Laser-Cut MDF

Listed below are some common uses for laser-cut MDF materials:

- Furniture

- Cabinets

- Stereo Speakers

- Roofing

- Doors Panels

- Store Fixtures/Signage

- Toys

- Musical Instruments

- High-Density Soundproofing

Furniture

Laser-cut MDF is often used in the fabrication of indoor furniture, as it is cheap and has a uniform surface finish. Aesthetic options like veneered MDF can further improve the overall look of standard MDF. Examples can include shelves and desks.

Cabinets

Cabinets are an ideal use case for laser-cut MDF, as they can be sturdy and low-cost when compared to their “real wood” alternatives. A veneered finish can improve aesthetics.

Stereo Speakers

MDF is an ideal material for stereo speaker boxes. It has a homogeneous structure and high density, characteristics which translate into good acoustic properties. This can improve the overall sound quality of the speaker without being as expensive as natural wood.

Roofing

Water-resistant MDF can be used for low-cost roofing as well as a backing for roof shingles. It is not an ideal roofing material but can be used for applications that do not require long-term durability such as temporary shelters.

Doors Panels

MDF can be used to create door panels and when laser cut, intricate and artistic designs can be created with minimal cost either through engraving or cutting.

Store Fixtures/Signage

Because MDF is inexpensive, one common use of laser-cut MDF boards is for signage. Complex company logos and designs can easily be laser cut.

Toys

Affordable MDF toys can be produced by laser cutting. The laser cutter can produce complex and interesting toys, including jigsaw puzzles, model kits, and doll houses.

Musical Instruments

MDF's high density and low cost make it ideal for use in low-cost musical instruments. MDF parts can be found in pianos, guitars, and drum kits. It must be noted that MDF is not used for its acoustic properties as it behaves as a sound insulator so it is used in areas where the transmission of sound is not required.

High-Density Soundproofing

MDF has high density and as such is an excellent soundproofing material. Examples can include recording studios and home theaters.

Alternatives to Laser Cutting MDF

While laser cutting MDF can be a cost-effective and versatile method for producing parts, it may not always be applicable. Listed below are some potential alternatives:

- Table Saw

- CNC Machining

- Table Saw: When cutting simple, straight designs, it may be more cost-effective to simply use a table saw to cut the required parts. Table saws are ideal for cutting rectangular components. However, chipping can occur on the cut edge.

- CNC Machining: For more complex designs, CNC routers can be used to cut MDF. A router is a type of CNC machine designed to cut wooden boards. Complex 3D dimensional engravings are possible using a router, as well as detailed 2D profiles.

Why Choose Xometry for MDF Laser Cutting Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.